PLANNING AND DEVELOPMENT

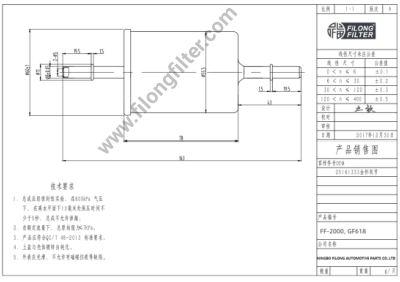

We design all our products with CAD-CAM-SCANNER systems, through prototyping and assembly and operation simulations for each component and for each finished product, with performance tests performed in independent laboratories.

This is why we¡¯re the logical choice to produce quality products for OEM contracts and leading automakers.

Test on components and finished products

Pressure pulses and burst UNI ISO 4548/6

Head loss, Filtration efficiency,

Storage capacity UNI ISO 5011:2000

Fuel filter seal UNI ISO 3724:2007

Burst of fuel filters UNI ISO 2941:2009

Pressure drop fuel filters UNI ISO 3969:2001

A fundamental part of our production process is the constant control of every detail. We are equipped with in-line testing systems that verify 100% of the filters produced and we have a laboratory inside where checks are carried out on the incoming materials and functional tests on the finished products.

High-performance

Raw Materials

We use our almost 30 years of experience to choose the best raw materials for products, ensuring safety, performance, sustainability, and cost-effectiveness. Compliant and specific

¡¤ Filter media pleating with rotary and alternative technology

¡¤ Filter media assemblies using infrared and ultrasonic technology

¡¤ Metal component molding with mechanical and hydraulic presses

¡¤ Polyurethane component molding with rotating machines